汽车索引钻井机的设计与制作 - 机械项目188金宝搏怎么样

ABSTRACT

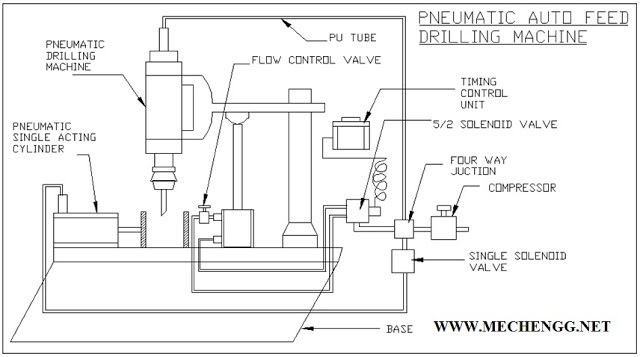

Quality and productivity play important role in today’s manufacturing market. Automation providing high end quality. Now a day’s due to very stiff and cut throat competitive market condition in manufacturing industries.

行业的主要目标显示,以最低成本生产更优质的产品,提高生产力。钻孔机是最重要的,普通的机器用于生产机器部件的孔操作,具有欲望表面质量和成本约束。获得公司质量和生产力的主要目标。在目前的项目中,由于安装,拆卸,标记等而导致响应输出参数(如生产孔,工作量,工作质量,工作质量,工作质量,工作量,工作质量,工作量)的安装,拆卸,标记等,以减少加工避险时间参数的效果。这是通过使用索引来完成的。努力调查生产孔的最佳时间及其对生产更好的表面质量和更高生产率的贡献,较低的自动化。

行业的主要目标显示,以最低成本生产更优质的产品,提高生产力。钻孔机是最重要的,普通的机器用于生产机器部件的孔操作,具有欲望表面质量和成本约束。获得公司质量和生产力的主要目标。在目前的项目中,由于安装,拆卸,标记等而导致响应输出参数(如生产孔,工作量,工作质量,工作质量,工作质量,工作量,工作质量,工作量)的安装,拆卸,标记等,以减少加工避险时间参数的效果。这是通过使用索引来完成的。努力调查生产孔的最佳时间及其对生产更好的表面质量和更高生产率的贡献,较低的自动化。

INTRODUCTION

沿PCD钻井过程非常常用。两个轮车车辆中的大多数都有盘式制动器,沿PCD,联轴器,飞轮等具有孔,以满足此类工作的需求,在NCS,CNC等上进行制造。这种加工技术的主要难度是巨大资本的要求熟练的运营商。因此,该钻孔机分度机构专注于设计简单的钻头,其中在钻头中不会从一个位置携带到其他位置,但是工作本身将在这样的情况下对齐

时尚,在简单的蠕虫旋转上,将实现新的位置。

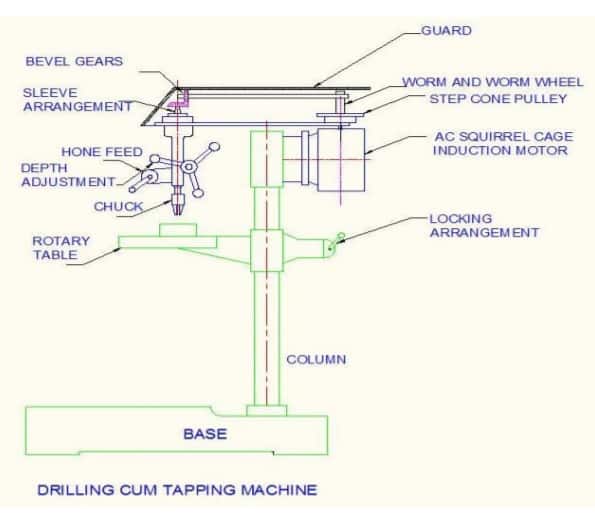

Based on simple engineering knowledge, assembly is designed and fabricated so as to reduce over head losses when it comes to drilling along PCD (Pitch Circle Diameter). Indexing process is well known to us when it comes to gear manufacturing but we are introducing same process but without bulky indexing plate assembly in drilling operation. The construction consists of assembly of worm and worm wheel mounted on vertical shaft which further carries Rotary round table on upper side with sensor. The indexing table is powered by small electrical motor. The speed of table is control by the speed regulator. The operator needs to rotate worm through few degrees to achieve desired Position of the job which contains the several holes.

沿PCD钻井过程非常常用。两个轮车车辆中的大多数都有盘式制动器,沿PCD,联轴器,飞轮等具有孔,以满足此类工作的需求,在NCS,CNC等上进行制造。这种加工技术的主要难度是巨大资本的要求熟练的运营商。因此,该钻孔机分度机构专注于设计简单的钻头,其中在钻头中不会从一个位置携带到其他位置,但是工作本身将在这样的情况下对齐

时尚,在简单的蠕虫旋转上,将实现新的位置。

Based on simple engineering knowledge, assembly is designed and fabricated so as to reduce over head losses when it comes to drilling along PCD (Pitch Circle Diameter). Indexing process is well known to us when it comes to gear manufacturing but we are introducing same process but without bulky indexing plate assembly in drilling operation. The construction consists of assembly of worm and worm wheel mounted on vertical shaft which further carries Rotary round table on upper side with sensor. The indexing table is powered by small electrical motor. The speed of table is control by the speed regulator. The operator needs to rotate worm through few degrees to achieve desired Position of the job which contains the several holes.

与可用的分度机制相比,这种钻井机器分度机制的成本相当较少。

同样,与其他自动化机相比,这里的投资很低。因此,该钻孔机分度机构具有低初始成本,低运营成本,低维护成本和低构建成本。

由于没有用电来产生旋转运动,因此没有电损耗。这些日子制造处理自动化和高科技过程消耗巨大的电源。在这种情况下,我们的钻井机器索引机制不仅提供了速度,还提供了手动处理。

同样,与其他自动化机相比,这里的投资很低。因此,该钻孔机分度机构具有低初始成本,低运营成本,低维护成本和低构建成本。

由于没有用电来产生旋转运动,因此没有电损耗。这些日子制造处理自动化和高科技过程消耗巨大的电源。在这种情况下,我们的钻井机器索引机制不仅提供了速度,还提供了手动处理。

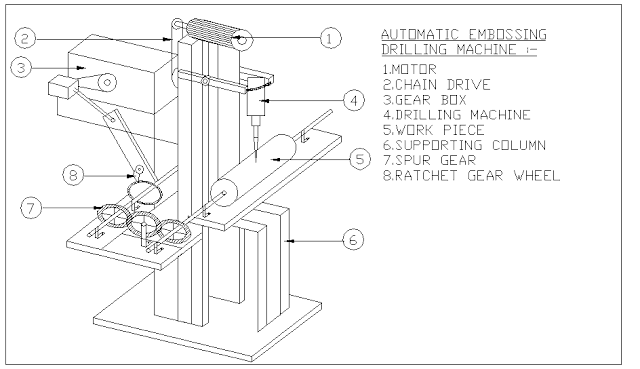

展示机制的构建

索引机制主要由蜗杆和蜗轮组成。在该设置中,蜗杆和蜗轮设置与垂直轴连接,在其上连接可拆卸旋转台。对于蜗杆的自动旋转和蜗杆轮设置小电机与V皮带的帮助相结合。旋转台的自动旋转通过根据要求使用传感器来控制。作为必须钻孔的工作安装在旋转台上,旋转台具有适合作业的某些孔或夹紧设置。

索引机制的工作

在该机制中,上圆形表旋转,其根据要求具有标记。标记是角度,我们必须索引表格。该标记只不过是可以通过接近传感器和接近传感器检测的金属止动件,即仅打破电流电路以停止旋转台。这导致准确角位移的索引。

在该机制中,上圆形表旋转,其根据要求具有标记。标记是角度,我们必须索引表格。该标记只不过是可以通过接近传感器和接近传感器检测的金属止动件,即仅打破电流电路以停止旋转台。这导致准确角位移的索引。

文献调查

Ranjeet Mithari and Amar Patil

Abstract – This paper describe the welding Positioner with auto indexing which is very important for mass production industries related with circular welding. As it depends upon the skill of worker to move electrode along the welding line. This special device can rotate the job at fixed rate to assist the welding process for circular components and ensure good profile and homogenous welding. This model has applications in small cylinder welding, compressors, and bottle filling plants etc. Automated welding Positioner machine for circular weld is totally satisfying the requirements. For this system Worm and worm wheel, Cummutator motor, Belt drive, Proximity sensor, Ball bearing, Electronic relay, Inching switch, inputs are required.

CONCLUSION

从上面的结果中可以说,我们降低了总分度机制可以减少简单钻孔机中批量生产的总制造时间。因此,它降低了劳动力成本并增加了生产。该机制还提供钻井操作的索引。

我在设计一个全自动专用铣床的过程中,以磨削茶园CTC滚筒。

我正在寻找一个自动索引Arrrn的稳点设计。

If you provide, shall be grateful and thanksful.

问候