Table of Contents

Shaping Machine – Introduction

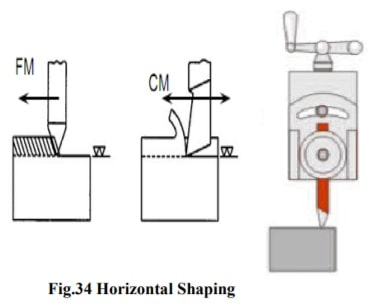

- Shaping is a process of machining a flat surface which may be horizontal, vertical, inclined, concave, or convex using a reciprocating single point tool. A shaping machine is a reciprocating type of machine tool.

- The work is held firmly on the table and the ram is allowed to reciprocate over it. A single point cutting tool is attached to the ram. When the ram moves horizontally in the forward direction, the tool removes metal from the work. On the return stroke, metal is not removed. The ram moves at a slow speed during the forward stroke. But during the return stroke, the ram moves at a faster speed.

- Though the distances of ram movement during the forward and return stroke remain the same, the time taken by the return stroke is less as it is faster. It is possible by the ‘Quick return mechanism’. In a shaping machine, a flat horizontal surface is machined by moving the work mounted on the table in a cross direction to the tool movement.

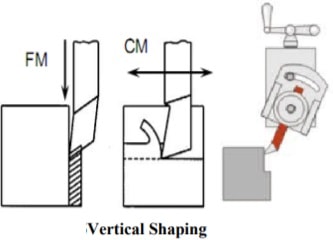

- When vertical surfaces are machined, the feed is given to the tool. When an inclined surface is machined, the vertical slide of the tool head is swiveled to the required angle and the feed is given to the tool by rotating the down feed handwheel.

Classification Of Shaper Machine :

1.根据对RAM的往复运动:

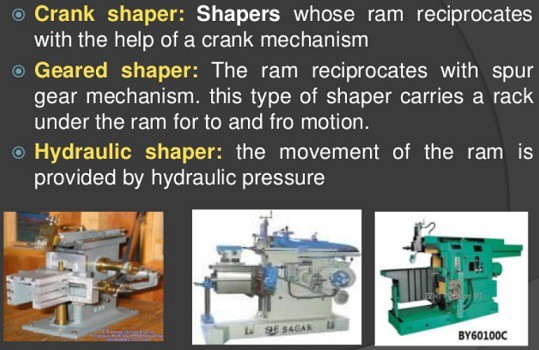

a)曲柄型成形器。

The crank and slotted link mechanism of a crank type shaper converts the rotation of an electric motor into the reciprocating movement of the ram. Though the lengths of both the forward and return strokes are equal, the ram travels at a faster speed during the return stroke. This quick return is incorporated in almost all types of shaper.

b) Geared type shaper.

RAM在某种类型的塑形器中的往复运动利用架子和小齿轮会影响。用刺齿轮直接在公羊网眼下方切开的齿条齿。带架子的小齿轮网缝由齿轮列车驱动。机器将穿越的速度和方向取决于齿轮的数量

the gear train. This type of shaper in not very widely used

c)液压塑形器

液压塑形器的公羊连接到活塞。高压处的油被泵送到液压系统的圆柱体上。当油推动活塞时,RAM会互动。液压塑料是高电动机,用于重型工作。

2. According to the position and travel of the ram:

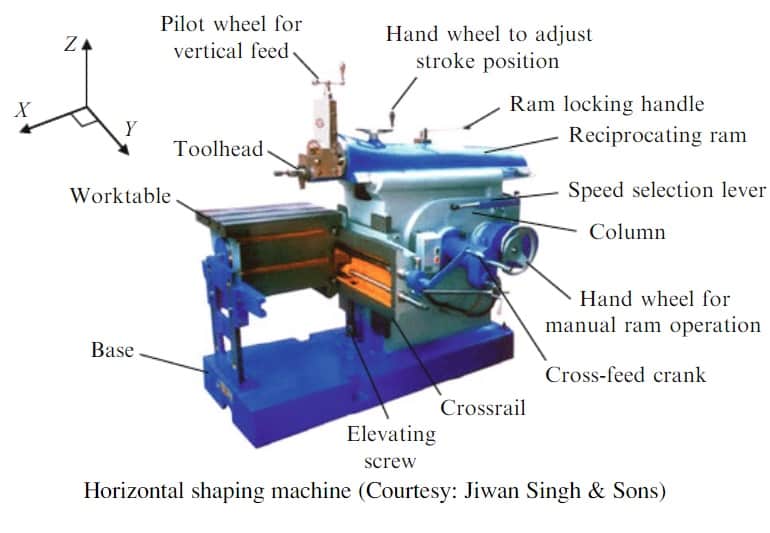

a) Horizontal shaper. –

In a horizontal shaper, the ram holding the tool reciprocates in a horizontal axis. Horizontal shapers are mainly used to produce flat surfaces.

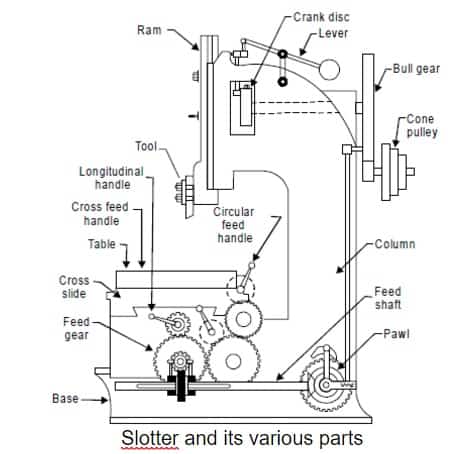

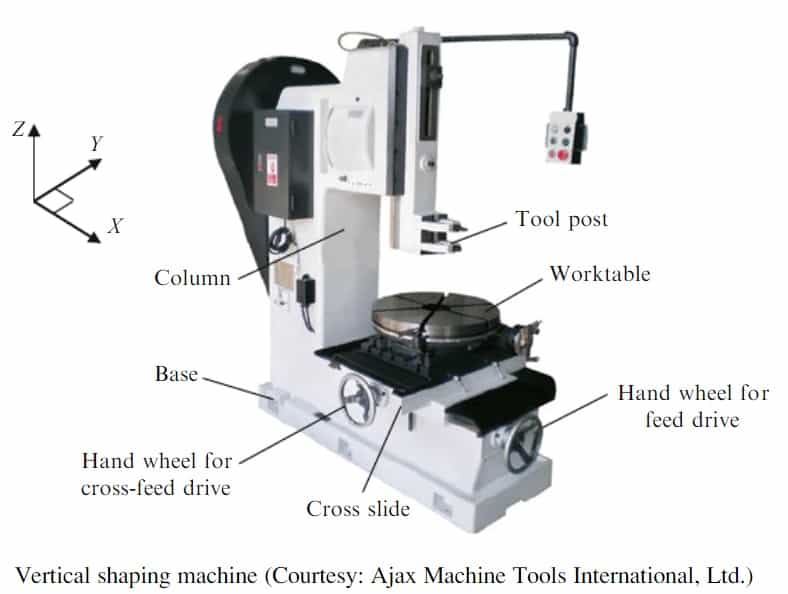

b) Vertical shaper.-

In a vertical shaper, the ram holding the tool reciprocates in a vertical axis. In some of the vertical machines provision is made to allow adjustment of the ram to an angle of about 10 degrees from the vertical position. Vertical shapers may be crank driven, rack driven, screw-driven, or hydraulic power-driven. The worktable of a vertical shaper can be given cross, longitudinal, and rotary movement. The tool used on a vertical shaper is entirely different from that used on a horizontal shaper. Vertical shapers are very convenient for machining internal surfaces, keyways, slots, or groves. Large internal and external gears may also be machined by the indexing arrangement of the rotary table. There are vertical shapers that are specially designed for machining internal keyways. They are then called key seaters.

c) Travelling Shaper-

In a traveling head shaper, the ram carrying the tool while it reciprocates moves crosswise to give the required feed. Heavy and unwieldy jobs which are very difficult to hold on the table of a standard fed past the tool are held static on the basement of the machine while the reciprocate and supplies the feeding movements.

3.根据桌子的设计类型

a) Standard shaper.

A shaper is termed as standard or plain when the table has only two movements, vertical and horizontal, to give the feed. The table may or may not be supported at the outer end.

b) Universal shaper.

In a universal shaper, in addition to the two movements provided on the table of the standard shaper, the table can be swiveled about an axis parallel to the ram ways, and the upper portion of the table can be tilted about a second horizontal axis perpendicular to the first axis. As the work mounted on the table can be adjusted in different planes, the machine is most suitable for different types of work and is given the name “Universal“. A universal is mostly used in tool room work.

4. Based on cutting stroke.

a) Push cut type.

This is the most general type of shaper used in common practice. The metal is removed when the ram moves away from the column, i.e pushes the work.

b) Draw cut type.

在拉动的塑造器中,当木板向机器的圆柱移动时,将金属卸下,即,将其绘制为机器的工作。该工具的设置为相反的方向到标准塑形器的方向。RAM通常由头顶支撑,可确保刚性并消除工具的挠度。在此塑形器中,切割压力朝着圆柱作用,该柱使横轨和其他轴承免受过多的订单,并可以进行深切口。这些机器中的振动实际上被消除了。

Read more:Types Of Shaping machine | Classification Of Shaper

Parts Of Shaper Machine :

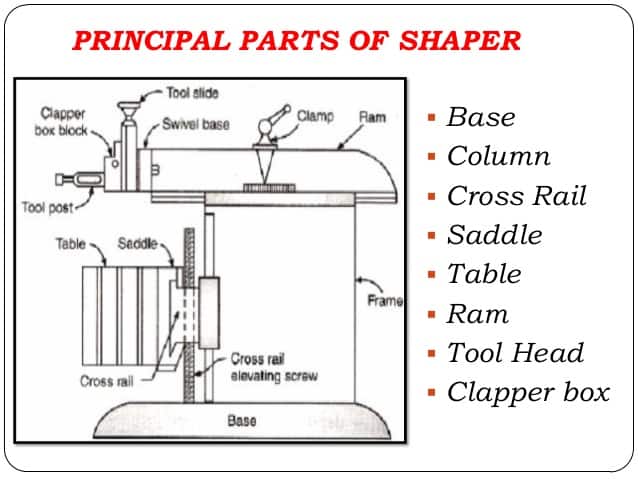

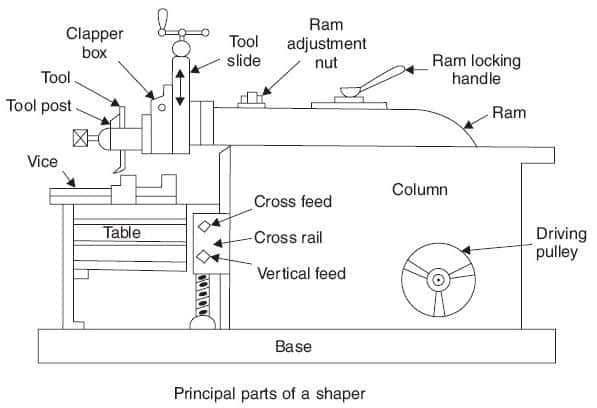

Base:

It is a heavy and robust cast iron body. The base supports the column or pillar which supports all the working parts such as ram, work-table, drive mechanism, etc.

柱或支柱:

该色谱柱是细胞结构的肋骨铸造。在台板上加工的同时,在列的顶部提供了RAM滑道。驱动RAM的曲柄和开槽的链路机构包含在列中。该列还包含驾驶电动机,可变速度变速箱,杠杆,手柄和其他控制装置。

内存:

Ram is a rigidly braced casting and is located on the top of the column. The ram slides back and forth in dovetail or square ways to transmit power to the cutter. The starting point and the length of the stroke can be adjusted using stroke positioning mechanism and the down feed mechanism.

工具头:

It is the device which holds the tool. The tool head slides in a dovetail at the front of the ram utilizing T-bolt sand is fastened to the ram on a circular plate so that it can be rotated for making angular cuts. It can swivel from 0° to 90° in a vertical plane. The tool head can be raised or lowered by hand feed for vertical cuts on the workpiece by its hand crank for precise depth adjustments.

Clapper Box:

The clapper box is needed because the cutter drags over the work on the return stroke. The clapper box is hinged so that the cutting too] will not dig in. Often this clapper box is automatically raised by mechanical, air, or hydraulic action.

十字架:

The Cross Rail is a heavy casting attached to the column at its front on the vertical guideways. It carries the horizontal table slideways. The cross rail can be raised or lowered using an elevating screw in order to compensate for different thicknesses of work.

Table:

It is made of cast iron and has box type construction. It holds and supports the work during the operation and slides along the cross rail to provide feed to the work. T-slots are provided on its top and sides for securing the work to it. The table is moved left and right, usually by hand, to position the work under the cutter when setting up. Then, either by hand or more often automatically, the table is moved sideways to feed the work under the cutter at the end or beginning of each stroke.

Saddle:

鞍座通常手动地上下移动(Y轴),以设置切割深度的粗糙位置。最终深度可以通过手动曲柄在工具头上设置。

Tool holders:

Tool holders are the same as the ones used on at engine lathe, though often larger. The cutter is sharpened with rake and clearance angles similar to lathe tools though the angles are smaller because the work surface is usually flat. These cutters are fastened into the tool holder.

Work holding:

工作持有经常在虎钳中进行。虎钳专门设计用于塑形器,具有很长的路,可以使下颚打开多达14英寸或更多,因此可以保留相当大的工件。虎钳也可能具有旋转底座,因此可以以一定角度进行切割。不能在虎钳中保存的工作(由于尺寸或形状)被直接夹在塑料桌上,与在铣床桌上固定的零件几乎相同。

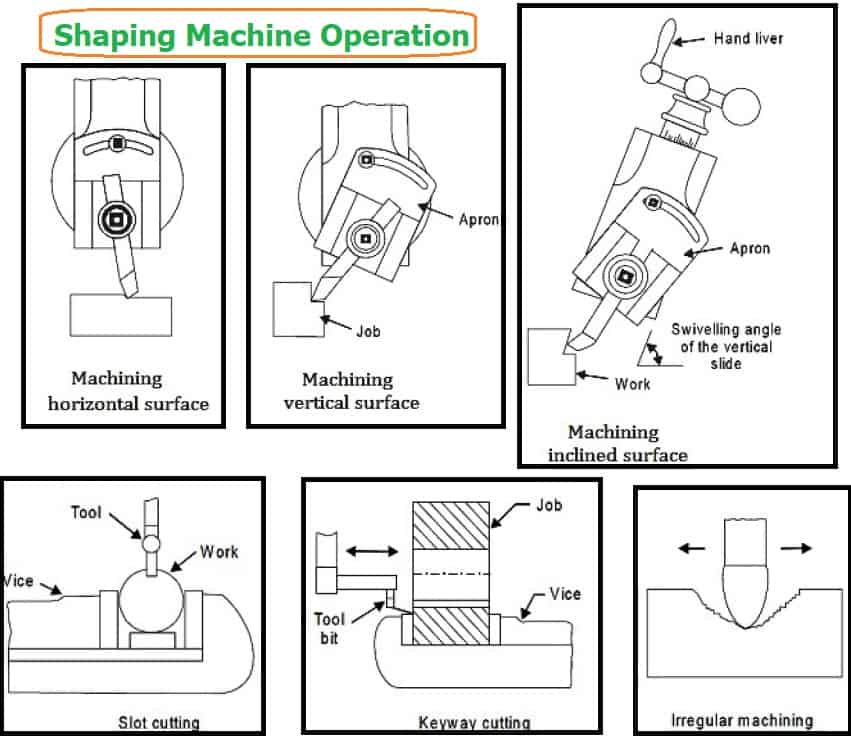

Shaper operations

A shaper is a machine tool primarily designed to generate a flat surface by a single-point cutting tool. Besides this, it may also be used to perform many other operations. The different operations, which a shaper can perform, are as follows:

1. Machining horizontal surface

2. Machining vertical surface

3. Machining inclined surface

4. Slot cutting

5. Keyways cutting

6. Machining irregular surface

7. Machining splines and cutting gears

加工水平表面

Set the vice jaws length perpendicular to the ram movement. Hold the job lengthwise parallel to the tool stroke so that the maximum stroke of the tool may be utilized. Hold the appropriate tool in the tool head. Set the proper inclination of the tool and depth of cut. Give cross feed to

该工具最初是手工直至剪切开始,然后采用动力饲料。重复上述程序。

Machining Vertical Surface:

The tool is fed downward in vertical cutting so swivel the clapper box from the face of the work to be cut. The tool is fed downwards by rotating the down feed screw by hand at the end of the return stroke. On the return stroke the tool swings away from the work and gives clearance, which prevents the work from being scratched. Start cutting from the highest point towards the bottom. Repeat the procedure for another cut.

Machining Angular Surface :

在这个刨机操作,一个角砍我s done at any angle other than a right angle to the horizontal or to the vertical plane. The work is set on the table and the vertical slide of the tooth head is swiveled to the required angle either towards the left or towards right from the vertical position.

The apron is then further swiveled away from the work so that the tool will clear the work during the return stroke. The down feed is given by rotating the down feed screw. The angular surface can also be machined in a universal shaper or by using a universal vice without swiveling the tool head.

Read More about Shaper Operation:Operation Performed On Shaping Machine Or Shaper.

成型机规范

The size of a shaper is determined by the maximum length of cut or stroke it can make. A standard shaper is usually capable of holding and machining a cube of the same dimensions as the length of stroke. The length of stroke is always the principal dimension, but a number of other details are also required for specifying a shaper fully.

The complete specification of a typical shaper is given below.

1. Length of stroke

2. Maximum horizontal travel of table

3. Maximum vertical travel of table

4.从桌到RAM的最大距离

5. Maximum vertical travel of tool slide

6. Length and width of table top

7. Length and depth of table side

8.电机功率

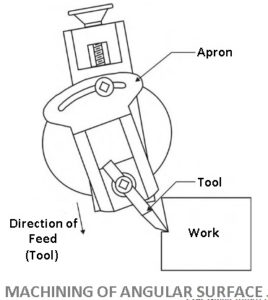

Shaper Machine Mechanism :

In a shaper rotary movement of the drive is converted into reciprocating movement by the mechanism contained within the column or frame of the machine. The ram holding the tool gets the reciprocating movement. In a standard shaper, metal is removed in the forward cutting stroke, while the return stroke goes idle and no metal is removed during this period. This mechanism is known as the quick return mechanism. The reciprocating movement of the ram and quick return mechanism of the machine usually obtained by anyone of the following methods:

1. Crank and slotted link mechanism

2. Whitworth quick return mechanism

3. Hydraulic shaper mechanism

- Since useful work is done only during the forward stroke of ram, the mechanism driving the ram is so designed that the return stroke is completed in much less time than the forward stroke.

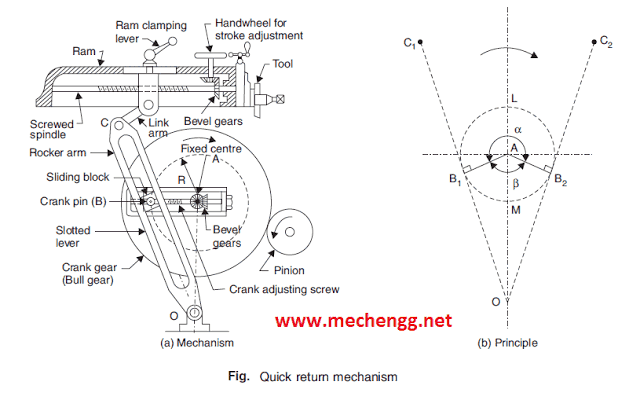

- The slotted lever quick return mechanism is illustrated in Figs. a and b

- The crank AB (of adjustable length R) rotates with a uniform angular speed. The crank pin B is in the shape of a die block which is free to slide inside the slot in the slotted lever OBC.

- 该开槽的杆在O处枢转,另一端C通过短链臂连接到RAM,如图(a)所示。

- When the crank AB rotates clockwise from position AB1 to AB2, the ram moves forward from left to right and when it rotates from position AB2 to AB1 the ram returns back to its original position.

- Clearly the time taken to complete forward stroke is proportional to angle (refer to Fig. (b))and the return stroke is completed in less time which is proportional to angle β

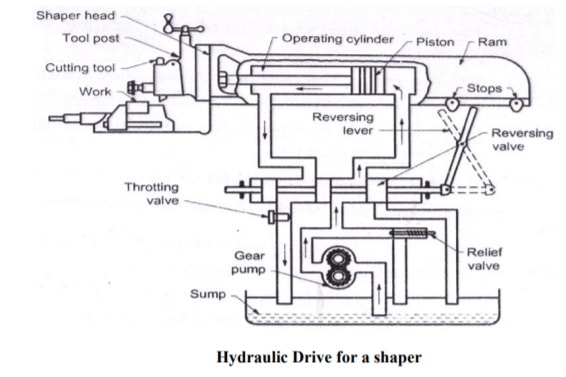

液压塑形机构

在液压塑形器中,RAM的往复运动是通过液压功率获得的。高压下的油被泵入装有活塞的操作缸中。活塞杆的末端连接到RAM。高压油首先作用于活塞的一侧,然后在另一侧作用,导致活塞往复运动,并将运动IST5传递到RAM上。通过改变泵输送的液体量来改变活塞速度。这种类型的塑形器最重要的优点之一是,从切割的开始到结束,RAM驱动器的切割速度和力是恒定的。它还提供了极大的速度和进料控制的灵活性。当切割工具被超载时,消除了冲击和允许运动或放慢运动的速度,从而保护零件或工具免于断裂。另一个优点是机器不会发出任何噪音并非常安静地运行。

Shaping Machine Parameter :

1)饲料:

饲料(S)是相对移动t of the work or tool in a direction perpendicular to the axis of reciprocation of the ram per double stroke. It is expressed in mm per stroke.

2)速度:

In a shaper, the cutting speed is the speed at which the metal is removed by the cutting tool in a period of one minute.

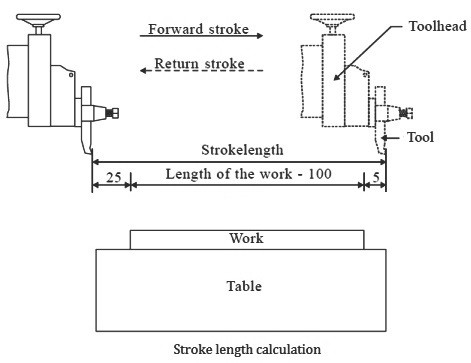

3) Stroke length calculation and adjustment

The length of the stroke is calculated to be nearly 30mm longer than the work. The position of the stroke is so adjusted that the tool starts to move from a distance of 25mm before the beginning of the cut and continues to move 5mm after the end of the cut. The figure shows the adjustment required for the stroke length calculation.

Question and Answer on Shaping Machine Click here

Shaper, Planer, Slotter machine | Interview Question and Answers

Reference :https://en.wikipedia.org/wiki/Shaper

More Resources /articles

Machine Tool Articles , notes , Interview Que & Ans

Machine Design Notes , article , Interview Que. and Ans.

Manufacturing Technology Notes , Articles

Mechanical Subjectwise Basic Concept Notes ,Articles